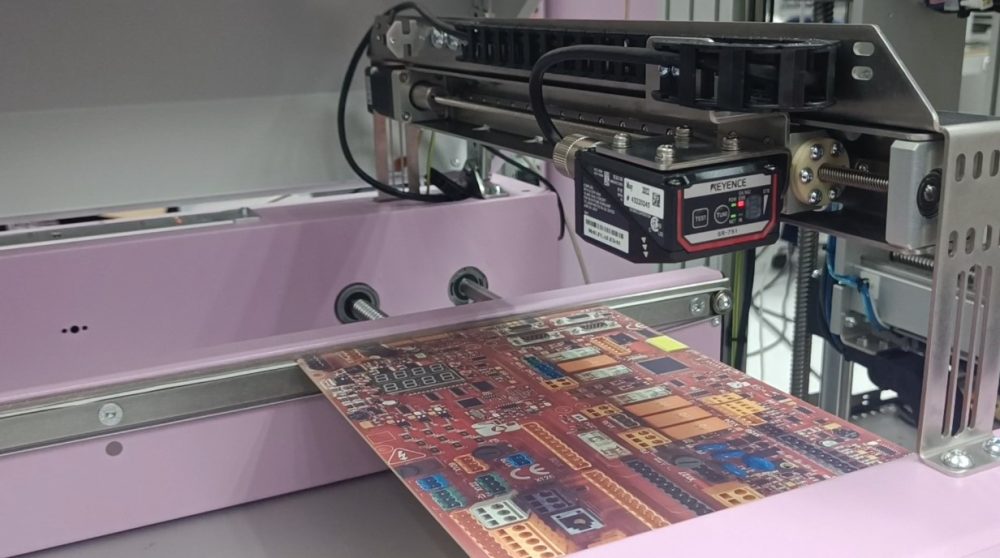

The header conveyors that are integrated into the in-line platforms combinations by 6TL include a system to adjust width automatically, which allows a quick adaptation to the different sizes of the DUTs to be tested. This adjustment will also be automatic in the continuous testing machine, generating a smooth and efficient process throughout the line.

In addition, the positioning of the header barcode reader is an automatic operation as well, ensuring the correct tracking of the DUT and avoiding possible errors.

Read more about the interconnectivity options for 6TL products by browsing our website.

#FastATE #InlineTestSystems #ReadyForTestAutomation