The Challenge

One of our customers, a leading encoder manufacturer, had one clear need: testing many PCBs at the same time without having to previously depanel the units. But there was another requirement, the process had to be performed in a platform that could be placed in a reduced space.

The main challenge was then minimizing the size of the test platform while allowing the in-panel test, but we also had to program all DUTs with only one programmer device. The test solution should allow more functionalities:

- Check LEDs intensity of DUT

- Read and print labels with SN and result after test sequence

- Possibility to test only one DUT disassembled

The Process

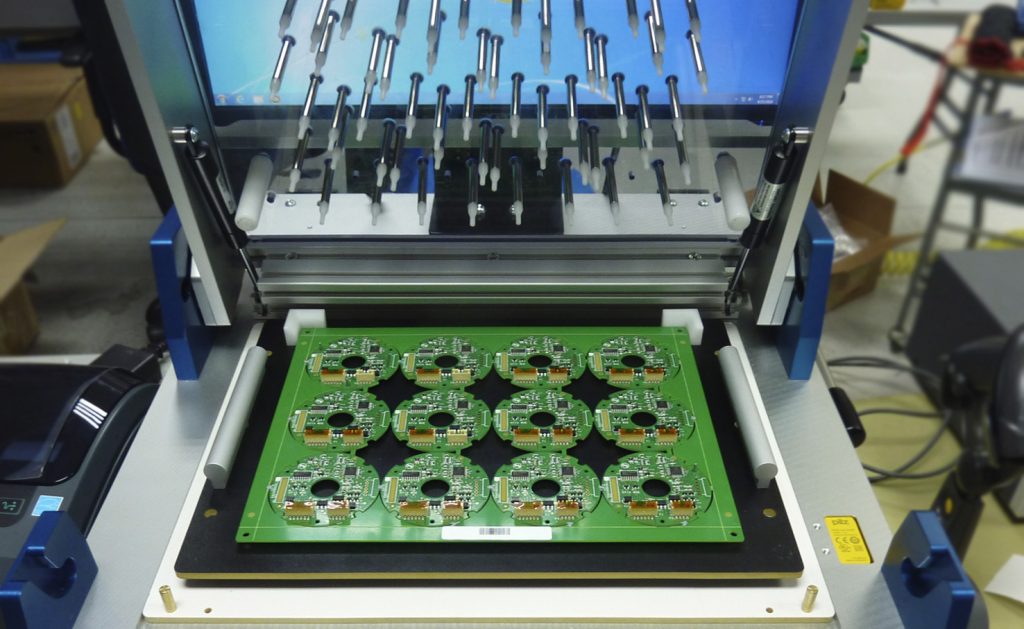

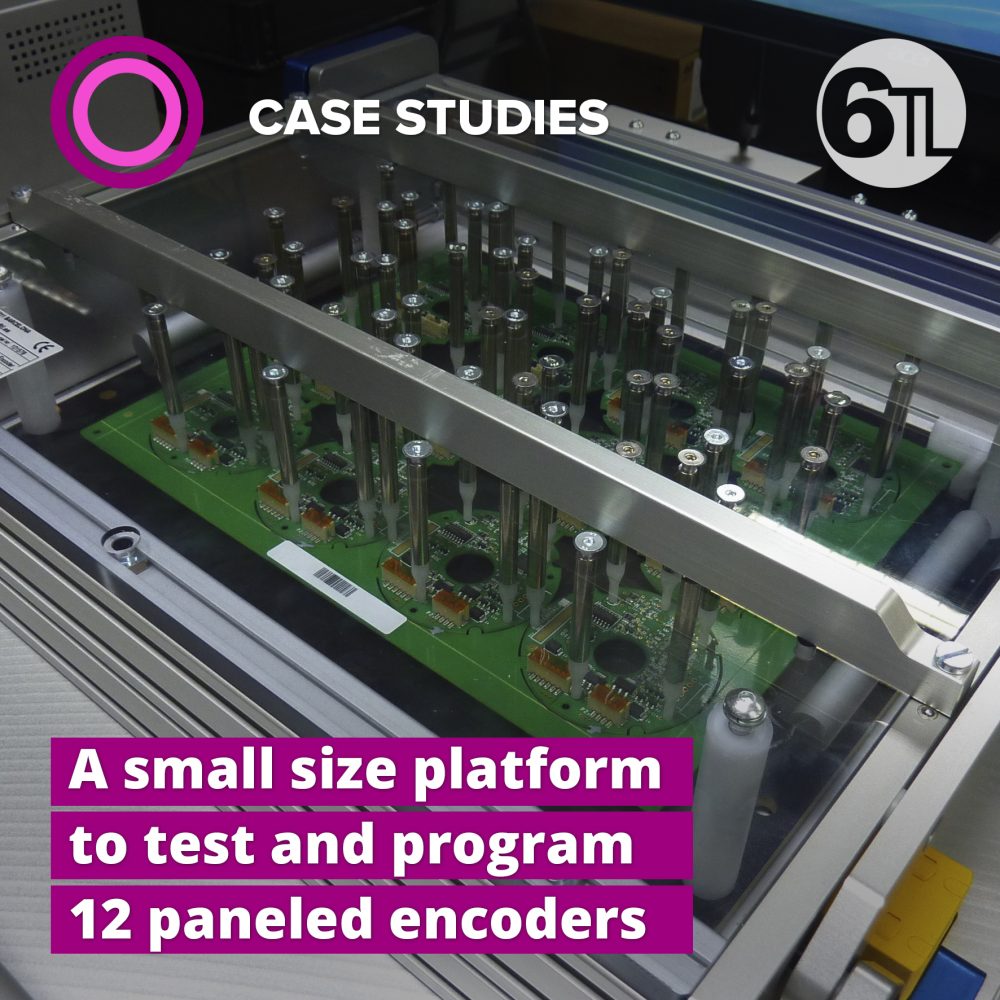

With the 6TL08 bench top test platform, we are able to test 12-DUT panel all at once using a compact test system. Using our YAV90059 module, we had capacity enough to multiplex all measurements for both DUTs and programming.

The FastATE® Technology allowed the integration of all instruments and traceability devices, like the NI VirtualBench or a barcode reader, in our Phi6 test software very easily, facilitating the operation tasks to our customer.

On the other hand, under request of our customer, a depanelled single DUT can also be tested, enabling the platform as an after-sales repair service. Thanks to the flexible multiplexer YAV90059, we could route all the needed signals for the firmware downloading and test of all encoders.

Conclusion

Thanks to FastATE® technology by 6TL, we could fulfill the specifications by integrating a test system and developing a test sequence in less than 4 weeks. With our portable and small size platform and its fixture, the customer was able to start production without delays. In addition, the exchangeable cassette system featured by the 6TL08 is adaptable to future projects the customer may have, which will also be executed using the same platform.